Heat Treatment Services

RIME provides services of heat treatment and heat treatment procedures for carrying out various kinds of heat treatment for pressure vessels, heat exchangers, columns, bullets and customized equipment.

- We carry out heat treatment on-site through our experienced technicians, using calibrated heat treatment equipment and instruments.

- Proper heat treatment procedure shall be submitted to avoid any distortion or damage. We also do stress calculation, support drawing, tools and equipment Designing, including thin-walled equipment for refineries.

- We establish optimum heat treatment for achieving desired properties.

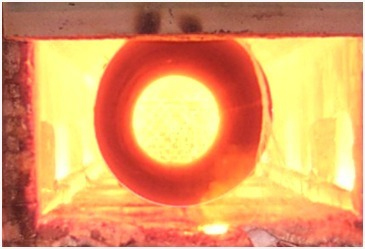

- We supply technicians and operators for operating fixed / other furnaces at clients’ workshop.

- We install modular furnaces (oil-fired / gas-fired / electrical method) and modular furnaces for heat treatment up to 720°C max. These furnaces can be modified / extended by providing furnace panels as per the job dimension.