At RIME, we have a panel of experts who can provide you solutions for your research and development requirements in various areas. Our experts can support you with R&D solutions to your day-to-day issues, and also provide you with full scale R&D support for setting up a new facility.

The following are some of the areas in which our panel of experts can be helpful to your business:

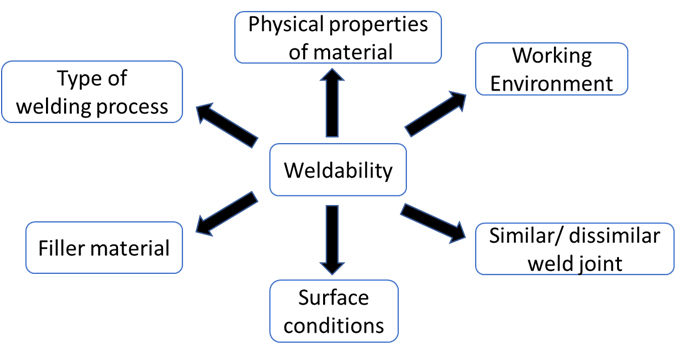

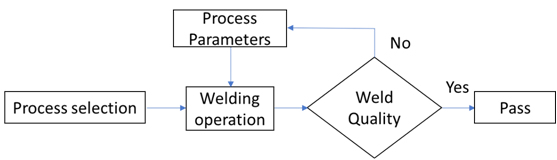

Selection of right welding consumables, establishing welding and heat treatment parameters for achieving the desired mechanical and corrosion properties; studying the effect of welding and heat treatment on HAZ and base metals.

Selection of the right combination of welding processes to enhance productivity and minimize cost.

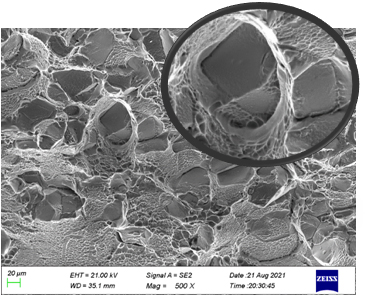

In a situation of non-achievement of desired properties or failure, thorough investigation shall be done by our experts and industrial solutions shall be provided.

Study of material properties in various service conditions, suggesting alternative materials, process optimization by studying process conditions and output desired.

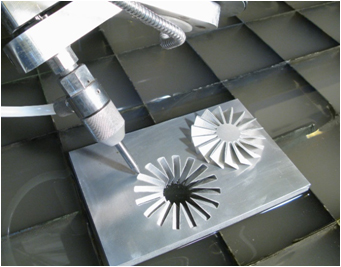

Machining of complex geometries with five axis CNC, tool path optimization, machining parameter optimization, tool life analysis, machining of hard to machine alloys, modelling and simulation of machining forces and process.

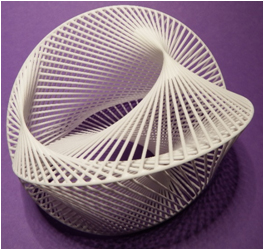

Fabrication of parts using polymer, metal and composite materials, Directed energy deposition of metallic materials, fused deposition of polymeric materials, process and parameter optimization for specific parts and designs, end-to-end delivery of complex parts using additive/subtractive processes.

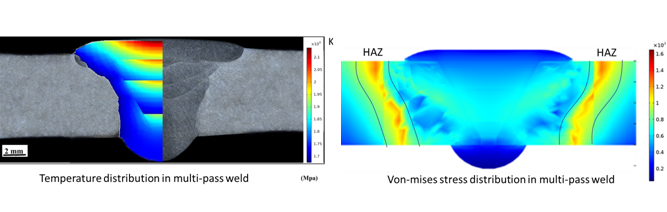

CFD based modelling of welding processes, casting simulation, die design for metal forming, finite element analysis, residual stress predictions, thermodynamic simulation for alloy design, precipitation and heat treatment optimization, microstructure modelling, and thermo-mechanical physical simulation. AI and ML based modelling for process optimization, defect identification, and industry 4.0 upgradation.